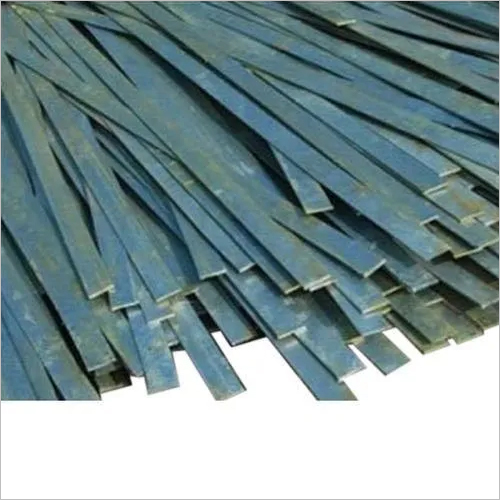

Galvanized Strips

Price 250000 INR/ Piece

MOQ : 10 Pieces

Galvanized Strips Specification

- Usage

- Industrial, Construction, Automotive, Electrical Appliances

- Alloy

- Galvanized Steel

- Surface Treatment

- Hot Dipped Galvanized

- Product Type

- Galvanized Strips

- Grade

- IS 277, ASTM A653, JIS G3302, EN 10346

- Shape

- Strip

- Thickness

- 0.15 mm to 3.0 mm

- Length

- Customizable, as per requirement

- Width

- 20 mm to 600 mm

- Application

- Cable Armouring, Ducting, Purlins, Sheet Metal Fabrication

- Color

- Silver

Galvanized Strips Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 400 Pieces Per Month

- Delivery Time

- 4-6 Week

About Galvanized Strips

We are offering a series of galvanized strips, which are a result of the process of hot dip galvanizing. This is an industrial protective coating which is beneficial for delivering a tough as well as durable protective coating for steel, which not just boosts its durability but also outlasts the design life. These GI Strips are commonly used in applications, where there is constant requirement of rust resistance. Our galvanized strips are offered at best prices and can be welded as per client's requirements.

Superior Rust Resistance for Demanding Environments

Our hot-dipped galvanized strips offer exceptional resistance to corrosion due to their premium zinc coating. Suitable for outdoor and humid environments, these strips help prolong the lifespan of structures and components exposed to harsh conditions, making them a preferred choice for industrial and construction projects.

Versatile Applications Across Industries

Galvanized strips are engineered to serve a wide range of uses, from cable armouring and ducting to purlins and sheet metal fabrication. Their excellent formability and customizable dimensions ensure adaptability to the requirements of construction, automotive, and electrical appliance manufacturing, enhancing operational versatility.

FAQs of Galvanized Strips:

Q: How are galvanized strips manufactured to ensure high rust resistance?

A: Galvanized strips are produced through a hot-dip galvanizing process, where steel strips are submerged in a bath of molten zinc. This process forms a strong, metallurgical bond between the zinc coating and the steel, ensuring enhanced rust resistance even in harsh environments.Q: What standards do your galvanized strips comply with?

A: Our galvanized strips adhere to international and Indian standards, including IS 277, ASTM A653, JIS G3302, EN 10346, IS, ISO, ASTM, DIN, and JIS specifications, ensuring consistent quality and reliability for global and domestic applications.Q: Where can these galvanized strips be used effectively?

A: These strips are well-suited for industrial, construction, cable armouring, ducting, purlin manufacturing, electrical appliances, and sheet metal fabrication. Their high tensile strength and formability make them adaptable for diverse environments and mechanical requirements.Q: What are the available thickness and width options for galvanized strips?

A: We offer galvanized strips in thicknesses ranging from 0.15 mm to 3.0 mm and widths between 20 mm to 600 mm. Both dimensions can be tailored to meet specific project or application requirements.Q: How does the temper type affect the performance of galvanized strips?

A: The temper of galvanized stripswhether soft, semi-hard, or full hardaffects their flexibility and strength. Soft tempers offer superior formability for intricate bending, while semi-hard and full hard are chosen for structural and load-bearing applications requiring higher strength.Q: What are the key benefits of using galvanized strips in manufacturing and construction?

A: Galvanized strips offer long-lasting corrosion protection, robust tensile strength, and excellent formability. These features reduce maintenance costs, extend component life, and ensure reliable performance in even the most challenging environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS