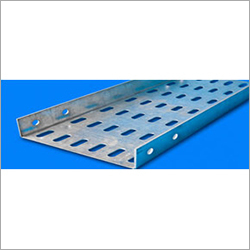

Hot Dip Galvanized Ladder Tray

Price 250000 INR/ Meter

MOQ : 250 Meters

Hot Dip Galvanized Ladder Tray Specification

- Deflection

- Less than 10 mm at max load

- Surface Finish

- Hot Dip Galvanized

- Max. Working Load

- Up to 150 kg/m (Depending on size and thickness)

- Product Type

- Ladder Tray

- Material

- Mild Steel (MS)

- Standard Thickness

- 1.6 mm, 2 mm, 2.5 mm, 3 mm

- Length

- 2500 mm

- Width

- 150 mm to 1200 mm

- Side Rail Height

- 50 mm to 150 mm

- Weight

- Varies with size and thickness

- Dimension (L*W*H)

- 2500 mm x (150-1200) mm x (50-150) mm

- Color

- Silver (metallic grey)

- Mounting Accessories

- Available on request (clamps, covers, bends, tees, etc.)

- Packing Type

- Bundle wrapped with HDPE/Plastic sheet

- Fire Resistance

- Yes

- Temperature Resistance

- -20°C to +300°C

- Installation Type

- Wall Mounted / Floor Mounted / Suspended

- Corrosion Protection

- Hot dip galvanized coating 70-80 microns

- Resistance to Chemicals

- High

- Application

- Electrical cable management in industrial, commercial, and infrastructure projects

- Rung Type

- Rectangular/Flat or Tubular

- Rung Spacing

- 250 mm (standard)

Hot Dip Galvanized Ladder Tray Trade Information

- Minimum Order Quantity

- 250 Meters

- Supply Ability

- 400 Meters Per Month

- Delivery Time

- 4-6 Week

- Packaging Details

- As per requirement

- Main Domestic Market

- All India

About Hot Dip Galvanized Ladder Tray

Hot Dip Galvanized Ladder Tray is extremely galvanized with its carbon steel and smooth polishing material. It is anti-corrosive to maintain its longer shelf life. This ladder is strong enough to tackle and prevent the short circuits. It is light weight and energy saving. Hot Dip Galvanized Ladder Trayis easy and fast to install to fix into various hard ware accessories. Therefore, provided has smooth edge to shield the wire cable safely. It is properly hinged with advance tools and techniques.

Other Detail:

- Condition: New

- Feature: Easy to Use

- Usage: Industrial

Superior Corrosion Protection

Each ladder tray undergoes a hot dip galvanization process, enveloping it in a protective layer up to 80 microns thick. This treatment ensures reliable performance even in harsh, chemically active environments, making the tray ideal for long-term industrial applications.

Flexible Installation Options

The ladder tray is designed for effortless adaptation, whether you need it wall mounted, floor mounted, or suspended. Available mounting accessories (like clamps and bends) simplify installation and customization, allowing tailored cable management even in complex project layouts.

High Load Capacity & Safety

Engineered to support up to 150 kg/m with less than 10 mm deflection, the tray guarantees dependable safety for electrical cables. Fire resistance and temperature tolerance from -20C to +300C further enhance suitability for demanding conditions.

FAQs of Hot Dip Galvanized Ladder Tray:

Q: How is the Hot Dip Galvanized Ladder Tray installed?

A: The ladder tray can be installed using wall mounting, floor mounting, or suspension methods. Mounting accessories, such as clamps and brackets, are available upon request to facilitate secure and adaptable installation for varied project requirements.Q: What are the main benefits of using this ladder tray in cable management?

A: The tray offers enhanced corrosion and chemical resistance due to its robust hot dip galvanized coating, high load-bearing capacity, fire resistance, and flexibility in installation. These features collectively ensure long-lasting, safe cable management in challenging industrial and commercial environments.Q: When should I request special mounting accessories for the ladder tray?

A: Special mounting accessories like covers, bends, tees, and clamps should be requested when your installation requires additional cable routing options, protection, or structural adaptations beyond standard setups.Q: Where can this ladder tray be used most effectively?

A: It is best suited for electrical cable management in industrial plants, commercial buildings, and large infrastructure projects that demand structured, reliable, and protected cable pathways.Q: What process is used to provide corrosion protection?

A: The tray undergoes hot dip galvanization, resulting in a durable metallic layer 70-80 microns thick. This method protects the mild steel from rust and chemical damage, prolonging the trays service life even in harsh environments.Q: How does the tray ensure safety against fire and extreme temperature?

A: Manufactured with fire-resistant properties and designed to withstand temperatures ranging from -20C to +300C, the ladder tray safeguards electrical cables under both normal and emergency conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cable Tray Category

Perforated Cable Tray

Price 250000 INR / Meter

Minimum Order Quantity : 250 Meters

Product Type : Other , Cable tray

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS